3D Printing and Prosthetics

Introduction to Prosthetics and their manufacture

Prosthetics are parts that fit into a human body to complete a function that has been lost/impaired. Ears cannot hear clearly; eyes have difficulty in seeing clearly; limbs have been cut off or were never present. Cochlear implants in the ear canal improve hearing; lenses are inserted into the retina to improve eyesight; artificial limbs aid walking and functioning of hands.

Traditional building materials like wood and metals cannot be easily shaped into complex curves to fit the human body. The method to shape traditional materials is to start with a block of material that is larger than the desired size and then, with various tools, chip away the excessive material till the final shape is acquired. In a generic manner, this is called the subtractive manufacturing.

Plastics are materials which, by definition, change shape under temperature and/or pressure, and they can be molded to fit the missing human parts. However, the traditional tools of molding plastics are based on making expensive high pressure dies whose economics require that identical pieces in millions are produced before the cost of the expensive die can be recovered. In the traditional plastic piece machine, after a die has been produced and placed in position, enough plastic to fill the die is melted and under, strong pressure, is pushed into the die. When some time has passed the plastic shapes itself into an accurate copy of the die. Broadly, this is called the injection molding manufacturing process.

While each organ has similar shape in all human beings, each human body and its organs also has many tiny variations in their shapes. To avoid pain and to improve the functioning, the ideal solution is that each prosthetic is custom made for each human being.

3D Printing

About twenty years ago a new method of manufacturing emerged that worked with thermoplastics but did away with the requirement of making a die. The new method also eliminated the injection molding machine. In essence, it melted a tiny amount of plastic at a time, and added that bit of plastic just precisely where it was required to be placed to reach the final shape.

Look at a plastic bucket just from the top (what engineers call a plan view). You should see a thick concentric circle representing the rim, and an inner circle representing the bottom of the bucket. This plan view hides the fact that the bucket has a side wall that gradually become wider as the height of the bucket increases. The bucket analogy draws attention to the fact that parts that fit into a human body occupy all the three dimensions in space: length, breadth and height.

A printer capable of printing into all the three dimensions is called 3D printer. Usually the materials it prints with are thermoplastics such as ABS and PTA. However there are printer that utilize sintering materials, and there are other printers that use lasers to cure floating plastic materials. What makes 3D printing exciting are the facts that (i) the cost of a 3D printer is rapidly spiraling down (ii) its capabilities are increasing (iii) the ecosystem of 3D printing is rapidly integrating so that a person wanting to print a custom design will readily find a good starting design and with it, a multitude of tools to change the design.

The Jaipur Foot approach to technology

The Jaipur Foot organisation has approached technology as a way to solve a social problem, i.e., how to re-empower differently-enabled people to acquire a social place in the society. Just as it has acquired other technologies and incorporated into its products with the aim of frugal engineering, Jaipur Foot is evaluating 3D printing for both Upper and Lower limb products. Before looking at 3D printing role in prosthetic limbs, let us look at two other areas of prosthetics.

Dental Prosthetics

In the field of dental prosthetics, where there is a hundred percent need for customization of each prosthetic, 3D printing has made no inroads. A dentist makes a mold of the needed teeth in his clinic, and sends the mold to a lab. There, technicians mix a set of colored acrylics (PMMA), pour it into the mold, and then either cold cure it or hot cure it to produce a fully customized dental prosthetic.

One reason for failure of 3D printing to make any inroads may be that 3D printed parts tend to be soft and may not be able to withstand the pressures inside the mouth.

Hearing Prosthetics

Traditional hearing aids were made with injection molding process, and in USA required fitments by certified persons. They were very expensive. The inside-the-ear-canal hearing aid caused pain due to parts being not customized to the ear.

Now, except for low cost and quality outside the ear hearing aids that continue to be made by injection molding process, 3D printing has taken over the field.

The field has progressed so far that certain vendors just require you to take a selfie of your ear and post it to them. From the picture, they generate a full 3D printed custom fit hearing aid. Many music lovers use such aids, along with apps on their mobile phone, to use the hearing aid as a no-pain music listening device. Others use them as low cost quality listening aids.

The reason for the success of 3D printing seems to be the elimination of the pain in the ear, improvements in quality of sound and the low cost, as the device is very small with the plastic part weighing only few grams.

3D Printing in Upper limb prosthetics

In India the largest case of disability in hands relate to cases of thrasher accidents where the victims have lost the hand till very near the shoulder. The second category of victims relate to those whose hands were lost either just above the elbow, or just below the elbow. The third category in terms of numbers are those who have lost the hand near the wrist. The fourth category is those who have lost a finger/thumb or were born without one.

For the victims in the third and fourth category there were no effective traditional solutions. For those in the second category, a mechanical hand produced by a PSU was the best solution. It provides very limited functionality. But the solution is at par with what National Health Service offers in UK and its cost is largely affordable.

For the largest category of people, i.e., near the shoulder loss of limb, the only solution was a myoelectric hand. It was not being manufactured in India and its costs were of the magnitude of Rs 4 lakhs per hand. The myoelectric hand restores a great deal of functionality to those who were lucky enough to afford it. The technology behind the myoelectric hand was largely secret and proprietary.

3D Printing solutions

Till the arrival of 3D printing, prosthetics were generally designed by orthopedic surgeons and their collaborative engineers. 3D printers enabled the victims to directly design and fabricate a solution for themselves. If a design did not work or was only partly successful, they could go on changing the design till they got something that worked.

Successful designs were placed in public domain for others to copy or to improve upon freely. Robohand press release describes the process as follows “Robohand started with Richard van As, when he had a woodworking accident in May 2011 severing all his fingers on his right hand. Straight out of hospital, Richard set to work in researching and developing a finger replacement for himself. He discovered after his accident that prosthetics are not affordable for the lay-man, and there are no functioning replacement digits. After creating his first few prototypes, Richard contacted Ivan Owen through the internet to ask if he would like to collaborate on the design of a replacement finger for tradesmen. Ivan had created a giant mechanical prop hand so was enthusiastic to join the project.”

Today that collaboration has grown into “Enabling the Future” organization that has volunteers in over 40 countries and had fitted hundreds of 3D printed hands to the needy. The design of the hand has undergone rapid changes and improvements.

For example, previously to fit a hand a number of measurements were required to be taken or a photo was required to be taken in a specific manner from which volunteers calculated the parameters for printing the hand. Today, one single parameter is required to be sent and a fully customized design, ready to print can be downloaded in matter of minutes.

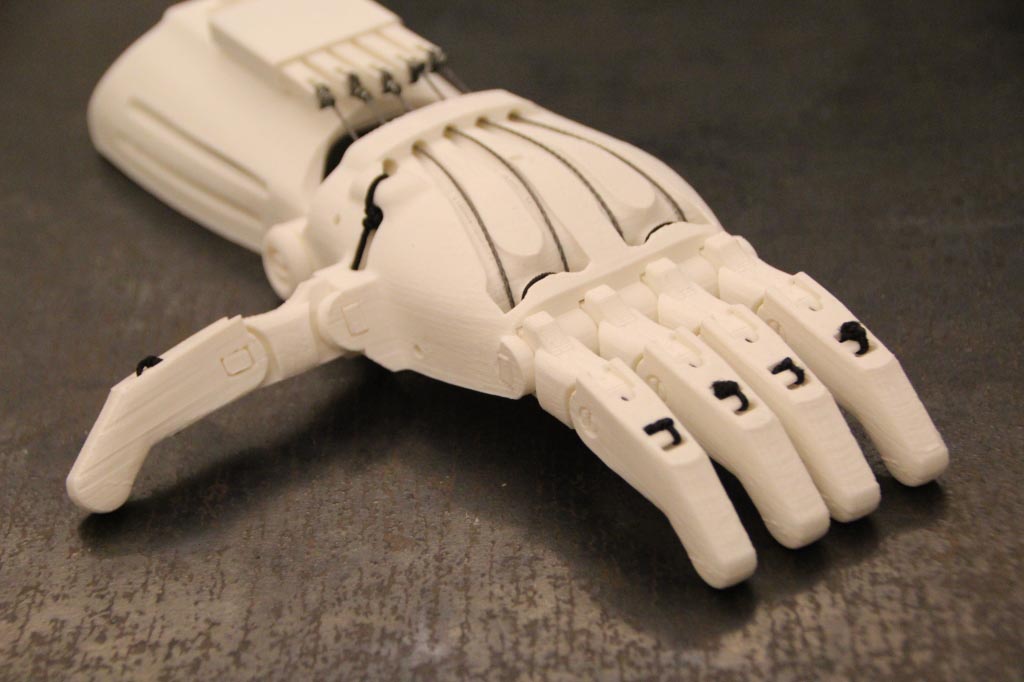

Read more about the progress enabling the future has made in the last two years here enablingthefuture.org/. A popular design of enablingthefuture.org is Raptor 2. A partially assembled hand is shown below.

The Raptor Reloaded

The Raptor Reloaded

There are a number of alternate 3D hand design that are also readily available. For example Steve Woods offers a design that is quite realistic. It is based on non-traditional plastic with a soft touch. See http://3dprint.com/57613/flex-hand-prosthetic/.

Steve Wood’s Flexy-Hand Filaflex

Steve Wood’s Flexy-Hand Filaflex

In general, small children (over the age of 5 years whose wrists can provide the power for the articulations of the fingers and the thumb) have greatly benefited from the fitted hand that can be easily discarded when they outgrow the existing size. The children are able to play many outdoor games and lift limited weights. It should be clear that such wrist powered hands do not provide all the functionality that myoelectric hands provide, but they change the life, and the perception of the life, of those fitted with it.

3D hands for near the elbow, or above the elbow have also been developed and they provide far more functionality than the mechanical prosthetics they replace.

One such device is called “Limbitless” and is available for about US $ 350 in USA. See http://enablingthefuture.org/2014/07/26/limbitless-6-year-old-gets-3d-printed-myoelectric-arm/

Another non-myoelectric hand is available for as little as US $ 50. See http://www.dailymail.co.uk/news/article-3019151/3-D-print-technology-providing-robohand-7-year-old-girl.html

In passing it should be noted that there are newly design 3D hand that do not place so much emphasis on customization in an effort to lower costs by standardization. To understand this approach think that instead of designing a shoe by measuring your feet, a shoe manufacturer makes shoes of a set of standard sizes one of which is very likely to fit you comfortably. I categorize the approach of University of Lowell Massachusetts as such an approach. In their words

"Engineering graduate students Jonathan DeAlderete, in mechanical engineering and Erin Keaney, in plastics engineering are the leaders of their new venture called Nonspec. Nonspec has designed prosthetic hands for children in emerging nations. This prosthetic differs from existing appliances because it was developed to be easily customizable while still being mass producible at a low cost."

Myoelectric hands

A myoelectric hand has four major components, namely

- The Plastic outer shell

- A muscle sensor

- A CPU to process the sensory inputs

- A motor with associated batteries and mechanical linkages to provide the motion.

Previously the plastic shell was a customized pipe. 3D printing enable the shell to be made to custom fit the stump. It also provides an easy way to hold the other components in their sockets.

The world of muscle sensor was shaken up by a new chip released about 2 years ago. It has now become a standardized way to pick the sensory inputs.

Computers on a chip such as Ardunio or Rasberry Pie have also lowered the CPU costs of a myoelectric hand.

Finally as stepper motors became common in Robotics and libraries to programme them became openly available, their costs have come tumbling down.

Overall the cost reductions in myoelectric hands is exemplified by the Bionic hand designed by Nicholas. He, himself has a near the shoulder disability. He designed the Bionic hand to solve his own problems. and then has placed the entire solution in public domain.

The Bionic hand was exhibited at Mumbai in January 2015 and is expected to cost about Rs 40,000.

Other organizations are also experimenting to reduce the cost of a myoelectric hand further.

3D Printing in lower limb prosthetics

While Jaipur Foot represents a constantly evolving technological artifact which is doing a satisfactory service to the society, 3D printing aims to improve all such artifacts.

One aim of 3D printing is to be solve a hidden problem with the existing lower limb prosthetics; namely that there is constant dull pain where the stump meets the prosthetics.

A Japanese team is trying to print a solution using its own designed 3D printer and a new type of silky soft filament. The new design of the printer allows it to print the prosthetic with two filaments, with most part with normal strong filament and the uppermost part with silky soft filament.

Another team is also trying to develop a new 3D printer to print the entire prosthetic in one go. See http://3dprintingindustry.com/2015/01/20/3d-printed-lower-limb-prosthetics-kickstarter/

University of Toronto has been producing a series of new designs and evaluating them. See http://3dprint.com/29030/sustainable-3d-prosthetics/

Scholarly articles are being written on design principles of lower limb prosthetics. See a new design paradigm for the development of custom-fit soft sockets for lower limb prostheses at

3D Printers

A 3D printer has a system of heating the plastic filament and then expelling a drop of it via a nozzle at an appropriate location.

This drop by drop addition technology has resulted in 3D printing called additive manufacturing.

For reaching the appropriate position, the 3 D printer uses stepper motors. To work in the third dimension. i.e.. height, a 3D printer uses another stepper motor to lower the printing bed, level by level. All these movements are dictated by a computer that gets its instructions in a peculiar file called STL file.

If there is a failure of electricity while the 3D printer is working, all the work done so far is a waste.

Similarly, if a nozzle gets clogged, then the work done till that point goes waste.

Lastly a new layer of material deposited may not stick well with the lower layer. Sooner or later that the part will fail and should be discarded as soon as the defect is visible.

One way to look at the field of 3D printers is to classify them according to price range.

The price range that is of interest to us is between US$ 400 to US $ 2,000.

3D printers in the price range $ 400 to $ 600 tend to be kits which require assembly by the buyers. They are good for hobbyists who want to learn about 3D printing. As they require frequent re-calibration, they are in production mode only occasionally. They tend to have small bed sizes and are limited to printing parts up to 4 inches by 4 inches.

3D printers in the price range US$ 800 to US $1400 come fully assembled. They are capable of printing up to 8 inches by 8 inches, and occasionally have a longer dimension in one direction. They can also print in greater height. Some of them can switch between two different types of filaments, i.e., ABS and PPA. Still others allow the simultaneous use of two types of/ two colors of filaments. Chosen with care such printers can print the long runs that prosthetic hands need.

3D Printers higher than $1400 have specialized functioning, including automated bed alignment and bed heating.

The key patents to 3D printing technology mostly expired in the year 2014, and most others will expire in the current year. Thus a race to reduce the prices and to improve the functionality is on. The share price of the erstwhile market leader in the field has been on a constant downward path.

3D Printing raw materials

The industry is trying to diversify the thermoplastic materials it uses as filaments to do the printing. However at the moment there are two dominant materials.

ABS, acrylonitile butadiene styrene or 'lego' plastic, is a very common choice for 3D printing. Its cost is about $5 to $ 10 more per kg than the alternative material PLA. It melts at a higher temperature than PLA, and is therefore more difficult to work with.

PLA, polylactic acid, is made from natural sources. It is available in soft and hard grades. It costs about $ 30 per kg, works at a lower temperature and is becoming very popular and may overtake ABS in the near future.

On the face of it the market for 3D printing raw materials looks like a competitive one; however the looks hide that fact in each category one company has a near monopoly hold on the market.